Our Cutting-Edge Equipment

Experience the Oaks Precision Fabricating advantage today

At Oaks Precision Fabricating, quality isn’t just a goal—it’s our standard.

Our investment in state-of-the-art equipment was chosen to ensure precision, efficiency, and superior results.

Experience the difference our cutting-edge equipment makes in your projects. Contact us today by calling 713-937-9190 to discuss your fabrication needs and discover how Oaks Precision Fabricating can exceed your expectations with precision, efficiency, and excellence.

Our Equipment Roster

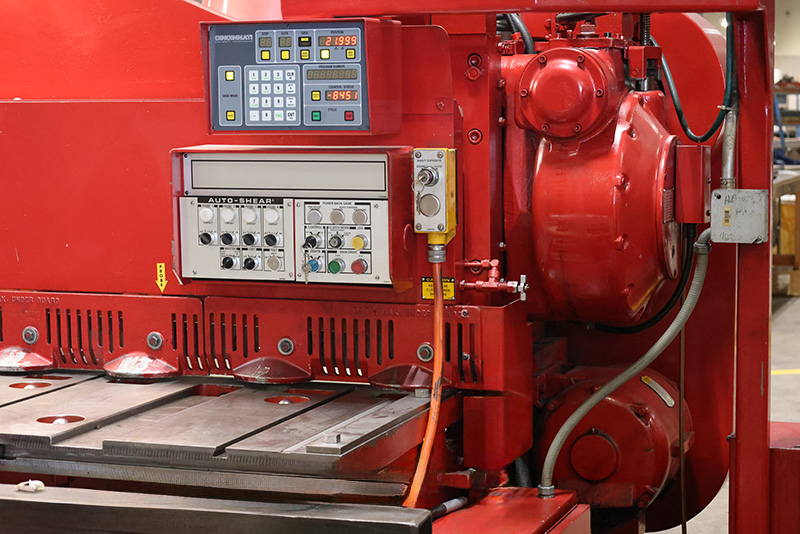

Our shear ensures precise cuts for a wide range of applications.

We can effortlessly handle cutting pipe and tubing with ease and accuracy.

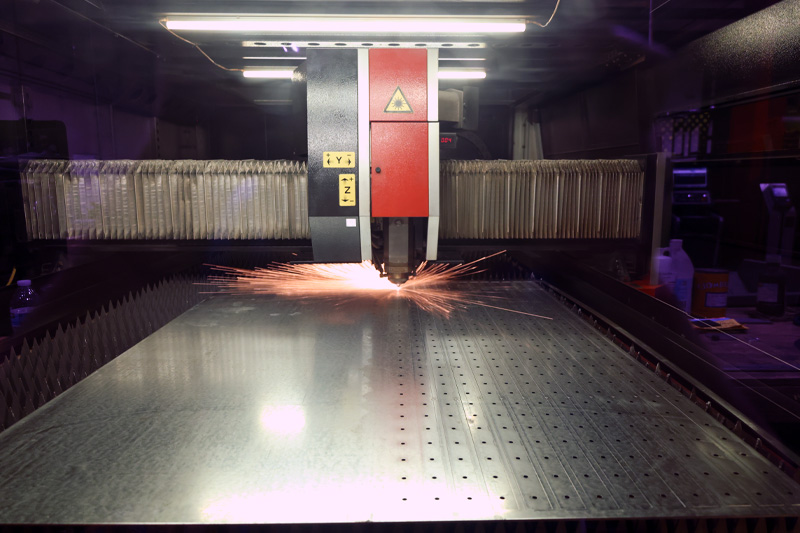

Featuring two fiber lasers, equipped with auto load tables and the capability to cut sheet sizes up to 60” x 120” and materials up to ½” thick, providing unparalleled versatility and speed. The auto-load tables allow for around-the-clock laser cutting.

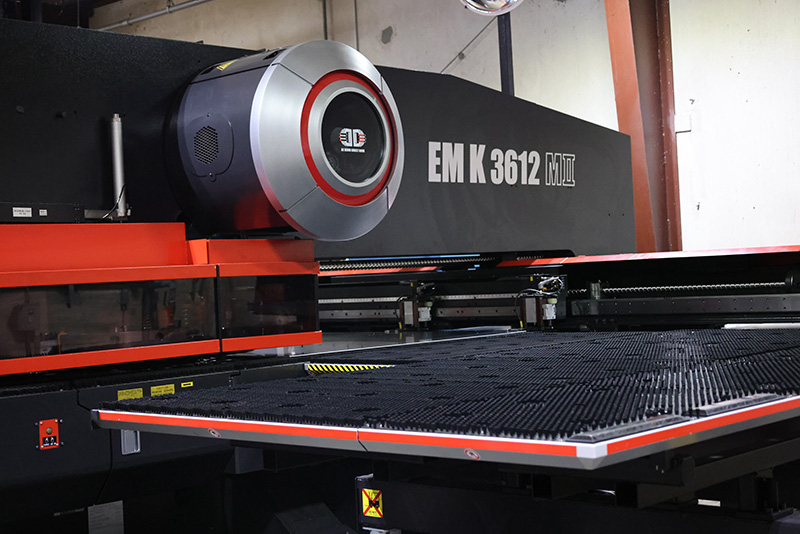

Our NC punch, paired with an auto load table for around-the-clock punching, handles materials up to ¼” thick and can be configured for tapping and countersinking holes while punching, ensuring consistent, precise, and efficient production.

Our programable precision press brakes can handle all types of forming requirements with accuracy and repeatability up to 13 feet in length.

With a capacity to roll up to 1/8” thick material, our 48” long power roller delivers precise rolling for a variety of applications.

We also utilize hardware insertion machines, pop rivet guns, and various handheld equipment for efficient and reliable product assembly.

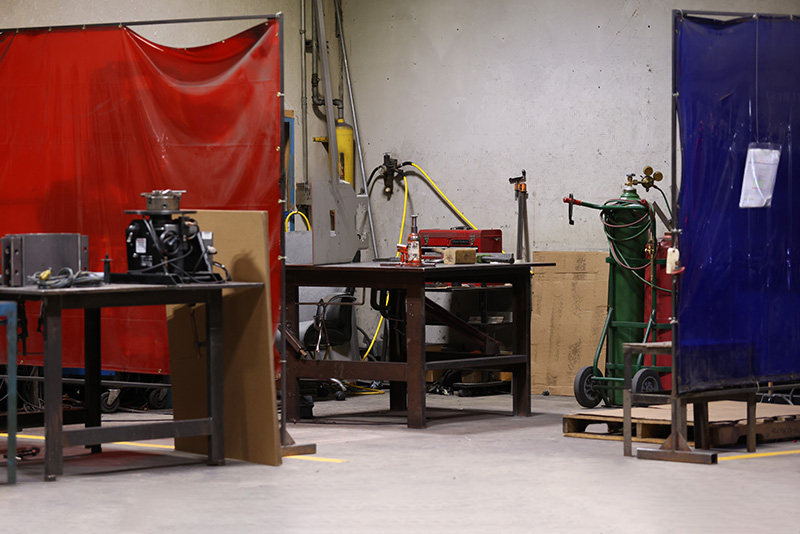

FCAW, TIG, MIG of mild steel, stainless steel, and aluminum, as well as spot welding capabilities to provide additional versatility. Our certified welders have the knowledge and talent to weld your project. From precision chassis and enclosures to larger cabinets and control boxes, we have the people in place to handle your welded assemblies.

Our metal finishing capabilities include a 36” wide panel sander, along with grinding, polishing, and orbital sanding, allowing us to deliver high-quality finishes.